Categories

Recent Posts

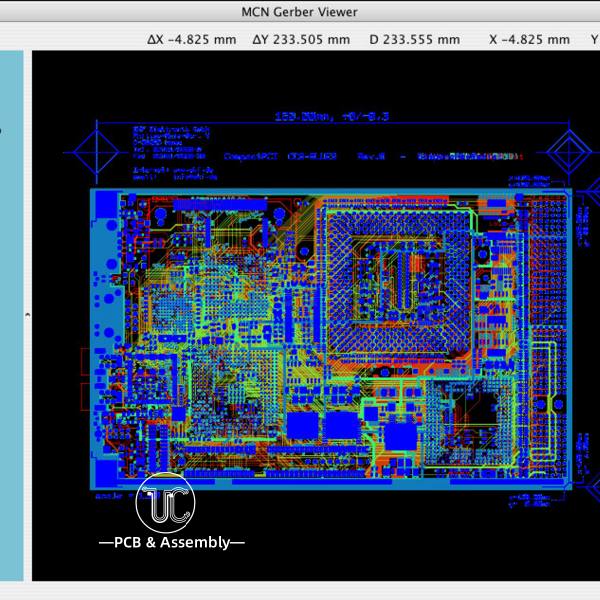

A Gerber file is a ‘light drawing’ of a PCB that contains specific parameters and is used as a standard file format for saving and transferring design blueprints. It is exported by a variety of CAD software and details the location of the components on the board, the thickness and orientation of the traces, and other information. This information is vital to the board manufacturer as it provides all the details needed for the manufacturing process, such as the physical properties of the PCB layers, the layout of the layers, etc.

Gerber files contain a wealth of information such as circuit board copper wires, soldermask pictures, character pictures, drill coordinates and attributes, and the outline of the physical board. This information provides manufacturers with precise guidance to ensure accurate and reliable soldering, avoiding problems such as shorted or poor soldering. Additionally, Gerber documentation helps manufacturers control solder quality during the production process by accurately controlling soldermask application with detailed soldermask information.

Gerber files play a vital role in the circuit board (PCB) design and production process. The following are the main uses of Gerber files:

In summary, circuit board Gerber documentation has an irreplaceable role in the circuit board manufacturing industry. It is a key guidance document that ensures accurate manufacturing and high quality production of circuit boards.

Related Posts:

2.Top 10 PCB Circuit Board Manufacturers In China

3.What Are The Different Types of PCBs?

4.Using 3D Electronic Component Models to Synch PCB and Enclosure Designs

5.What PCB Certificates Does Ucreate Have?

Welcome to consult our sales engineer with BOM list and Gerber file