Categories

Recent Posts

Copper is a common material used in circuit boards, especially for the conductive traces that connect various components and elements of the circuit. However, it is possible that the term "copper in the circuit board hole" may refer to different things, and I'll cover a few possibilities:

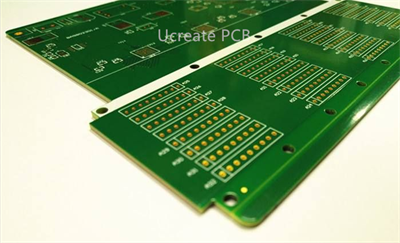

Plated Through-Holes (PTH): In traditional circuit boards, plated through-holes are holes drilled through the board that have a thin layer of copper deposited on their inner surfaces. This copper plating allows electrical signals to pass from one side of the board to the other, making connections between different layers of the board. If you don't see copper in a PTH, it might be due to insufficient plating or a manufacturing defect.

Related Posts:

What do through holes, blind holes and buried holes mean in printed circuit boards?

Through-hole technology Assembly

Non-Plated Through-Holes: Some circuit boards have non-plated through-holes, which means they lack the copper layer on the inner surfaces. These holes are used for mechanical support or as mounting holes for components without needing electrical connections.

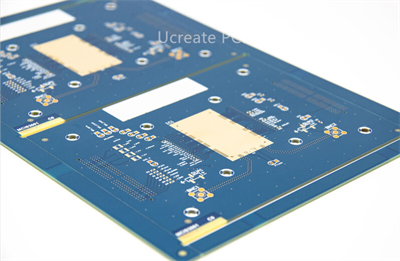

Hole Filling Process: In modern circuit board manufacturing, techniques like "hole filling" or "planarization" might be used to improve the performance of high-speed circuits. These techniques involve filling the holes with materials other than copper to optimize signal transmission and reduce signal loss.

Design Choices: The design of the circuit board might dictate the absence of copper in certain holes. For example, some holes may be intentionally left without copper connections to create breaks in the circuit or isolate specific areas.

For the holes where copper must be added in the circuit board but is not available, there are several reasons for this:

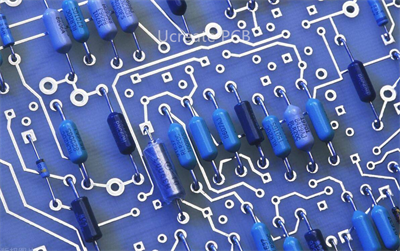

1. Lack of inner layer copper: In the manufacturing process of multilayer circuit boards, unnecessary copper foil is removed by chemical etching or mechanical scraping to form inner layer circuits. If a mistake or mishandling occurs during this process, it may result in the copper being deleted or missing in some holes.

2. Drilled hole uncoated charging: In circuit board manufacturing, holes are usually formed by drilling operations. Before drilling, the circuit board should be coated and charged to form a layer of copper film on the hole wall for the subsequent copper plating process. If the coating charge is incomplete or not performed, those voids will appear copper-free.

3. Poor copper plating: During the copper plating process of circuit board manufacturing, copper is electrochemically deposited on the surface and inside the holes to form a conductive layer. If there is a problem in the copper plating process, such as unstable current, contamination of the plating solution, or incorrect plating solution, it may cause some holes to be copper-free.

4. Improper anti-corrosion treatment: The circuit board needs anti-corrosion treatment during the manufacturing process to prevent oxidation and corrosion of the copper surface. If the anti-corrosion treatment is insufficient or incorrect, the copper in the hole may be corroded, forming a copper-free phenomenon.

When there is no copper in the circuit board hole, it may cause circuit connection failure, poor signal transmission or circuit failure. Therefore, in the circuit board manufacturing process, it is necessary to ensure the accuracy and quality control of each process step to avoid the occurrence of copper-free phenomenon.

Welcome to consult our sales engineer with BOM list and Gerber file