Categories

Recent Posts

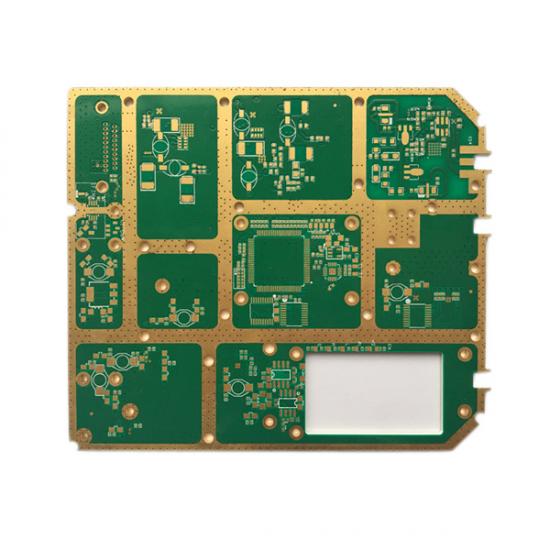

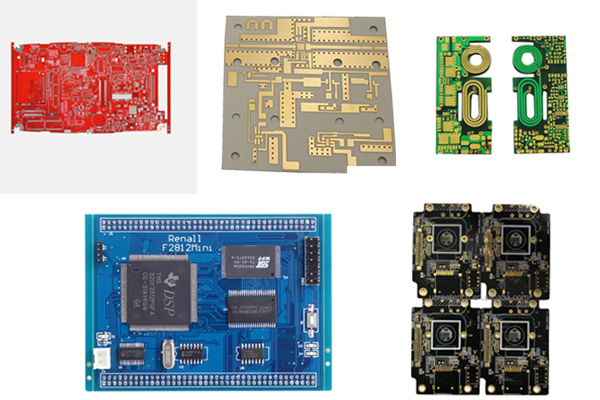

If you are asked what colour a printed circuit board is, I believe the first response is green. Printed circuit boards are basically made up of pads, vias, solder resist layers, silkscreen layers, copper traces, various components and other parts. Copper is a more active metal, in the air is easy to react with the oxygen in the air, in order to prevent copper vaporisation, will use a special ink, the layer of coated houses called solder resist layer, the use of materials for solder resist ink, careful friends can find that most of the common printed circuit boards are green, which is why? In fact, it is not necessarily green PCB, it depends on what colour the designer wants to make it that it is what colour.

We usually choose green because it does not irritate the eyes and it is not easy for production and maintenance personnel to look at printed circuit boards for long periods of time.

In terms of design, the colours commonly used are yellow, black and red. The various colours are all painted on the surface after they have been manufactured. Another reason why the most common colour is green is that PCB factories have the most spare is green ink, so the cost of green ink is relatively low. This is also because the different wiring is easier to distinguish from white when repairing printed circuit boards, whereas black and white are relatively difficult to see. Green ink allows for smaller errors, smaller areas and can be done with greater accuracy.

Send PCB Files to Sales@ucreatepcb.com, We Will Quote You Very Soon!

Request PCB Manufacturing Quote