Categories

Recent Posts

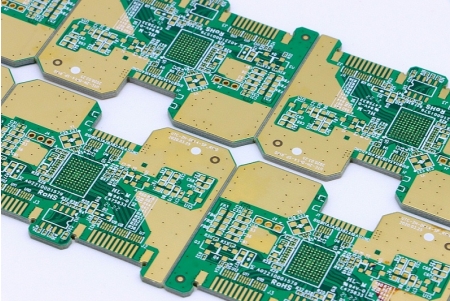

Immersion gold PCB (ENIG - Electroless Nickel Immersion Gold) and gold-plated circuit boards are both methods for applying a layer of gold onto the surface of a printed circuit board (PCB), but they use different processes and have distinct characteristics.

ENIG Finish PCB uses a chemical deposition method. It generates a layer of coating through a chemical oxidation-reduction reaction. It is generally thicker. It is a kind of chemical nickel gold layer deposition method and can achieve a thicker gold layer.

Gold plating is a more straightforward electrochemical process.It directly deposits a thicker layer of gold onto the PCB's copper traces through electroplating.

Gold plating uses the principle of electrolysis, also called electroplating. Most other metal surface treatments also use electroplating. Inactual product applications, 90% of gold boards are immersed gold circuit boards, because the poor weldability of gold plating pcb is its fatal shortcoming, and it is also the direct reason why many companies abandon the gold plating process!

The immersion gold plating process deposits a nickel-gold coating with stable color, good brightness, smooth coating and good solder ability on the surface of printed circuits. It can basically be divided into four stages: pre-treatment (oil removal, micro-etching, activation, post-immersion), nickel immersion, gold immersion, and post-treatment (waste gold washing, DI washing, drying). The thickness of immersion gold is between 0.025-0.1um. Gold is used for surface treatment of circuit boards because gold has strong conductivity, good oxidation resistance, and long life. It is generally used in keyboards, gold finger boards, etc. The most fundamental difference between gold plating on PCB and ENIG PCB is that gold plating is hard Gold (wear-resistant), immersion gold is soft gold (not wear-resistant). So, what are the main differences between immersion gold circuit boards and gold-plated circuit boards?

1. The crystal structure formed by immersion gold and gold plating are different. The thickness of gold in immersion gold is much thicker than gold plating. Immersion gold will be golden yellow, which is more yellow than gold plating (this is one of the methods to distinguish gold plating and immersion gold). The gold-plated one will be slightly white (the color of nickel).

2. The immersion gold PCB plating only has nickel gold on the pad. The signal transmission in the skin effect is in the copper layer and will not affect the signal Immersion gold has a denser crystal structure than gold plating and is less prone to oxidation. The immersion gold circuit board only has nickel gold on the pad, so the solder mask on the circuit is more firmly bonded with the copper layer. The project will not affect the spacing during compensation.

3. For boards with higher requirements and better flatness, immersion gold is generally used. Immersion gold generally does not cause black pads after assembly. The flatness and service life of immersed gold circuit boards are better than those of gold plated pcb boards.

4. As circuit board processing accuracy requirements become higher and higher,line width and spacing have reached below 0.1mm. Gold plating is prone to short circuits in the gold wire. The immersion gold circuit board only has nickel gold on the pad, so it is not easy to cause a gold wire short circuit.

ENIG is commonly used in applications where flatness, fine-pitch components, and solderability are critical, such as high-end consumer electronics and aerospace applications.

Gold plating is used in various applications, including connectors, switches, and decorative finishes. It is also used when a thicker gold layer is required for increased durability and electrical conductivity.

In summary, the choice between immersion gold (ENIG) and gold plating for a circuit board depends on the specific requirements of the application. ENIG provides a thinner, more even layer suitable for fine-pitch components and soldering, while gold plating offers a thicker layer and is more cost-effective for applications where a thicker gold layer is acceptable.

Uceate PCB Co., Ltd can produce all the surface finish PCB you needed. Such as: OSP,HASL,Imm Gold/Nickel/Ag, Electric gold. Not Sure If Your PCB Design Is Manufacturable? Send us your requirment to Sales@ucreatepcb.com, let our PCB engineer help for you.

Welcome to consult our sales engineer with BOM list and Gerber file