Categories

Recent Posts

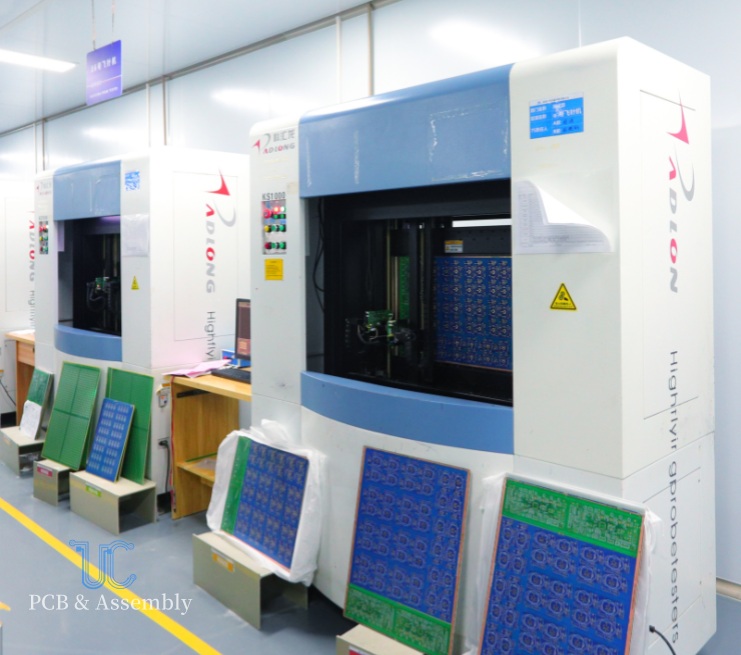

PCB flying probe test is an electronic circuit test method is mainly used to test the printed circuit board (PCB) on the electronic components and their connection performance.

What is the flying probe test?

Flying probe testing (FPT) uses four to eight independently controlled probes that are programmed to move through the air and access various component pins on a PCB one by one. During testing, the probes make contact with test pads and via holes to test the electrical performance of individual components. The flying probe tester is equipped with software that controls the movement of the probes and collects and analyses the test data.

Classification of flying probe test

Flying probe test can be classified according to different testing needs and PCB types, mainly including the following.

1. Passive test: mainly used to test the passive components on the PCB, such as resistance, capacitance, inductance and so on. The value of these components can be measured by flying probe tester to verify whether it meets the design requirements.

2. Active testing: In active testing, flying probe testers perform functional tests on active components (e.g. diodes, transistors, integrated circuits, etc.) on the PCB. This usually involves providing an appropriate excitation signal to the component and measuring its output response.

3. Open and short circuit test: Flying probe testers can also be used to detect open and short circuit faults on PCBs. By measuring the resistance or capacitance values between the probes, discontinuities or short-circuit points in the circuit can be identified.

Advantages of flying probe test

1. Flexibility: flying probe test without special fixtures, applicable to a variety of different designs of PCB, especially small quantities or custom products. This allows flying probe test can quickly adapt to changing production requirements.

2. High Efficiency: The test process is fast and parallel, multiple probes work simultaneously, significantly reducing the overall test time and improving production efficiency.

3. Cost savings: eliminating the high cost of making fixtures, especially in small batch production, reducing the initial investment and production costs.

4. High accuracy: the use of precision probes and advanced algorithms flying probe test can efficiently detect short circuits, open circuits and other issues, to ensure the electrical performance of the PCB.

In summary, flying probe test for circuit boards is an efficient, flexible and accurate test method, which plays an important role in the electronics manufacturing industry and helps to improve product quality, reduce production costs and improve production efficiency.

Related Posts:

2.What iS PTFE High Frequency Board?

3.Turnkey PCB Assembly Services.

4.How to Choose PCB Suppliers?

5.What is SMT patch wave soldering?

Welcome to consult our sales engineer with BOM list and Gerber file