Categories

Recent Posts

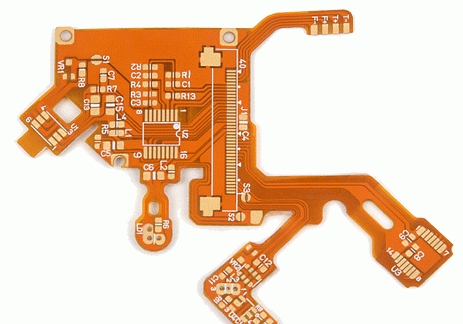

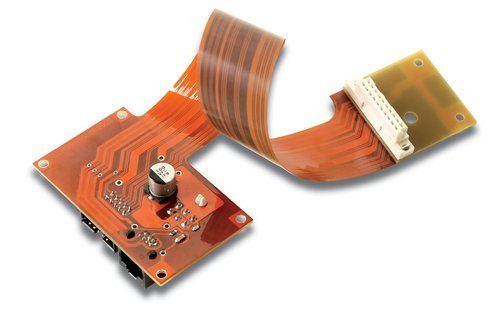

The Flexible Printed Circuit (FPC) industry plays a pivotal role in the realm of modern electronics, serving as a cornerstone for the seamless integration of technology into our daily lives. FPCs, also known as flexible circuits or flex circuits, represent a revolutionary departure from traditional rigid printed circuit boards (PCBs). Their flexible and adaptable nature allows them to conform to the contours of electronic devices, opening up new possibilities for design and functionality.

The FPC industry acts as a catalyst for innovation, enabling designers and engineers to push the boundaries of what is possible in electronic product development. The adaptability of FPCs empowers creative freedom, fostering the creation of revolutionary products that seamlessly integrate into our daily lives.

How to choose FPC factory?

Here are some tips for your reference:

1.Industry Experience and Reputation:

One of the primary considerations when choosing an FPC manufacturer is their industry experience and reputation. Look for manufacturers with a proven track record and a substantial history in the field. Consider the reputation of the manufacturer in terms of product quality, on-time delivery, and customer satisfaction. A manufacturer with a solid foundation in the industry is more likely to provide reliable and high-quality FPCs.

2.Technological Capabilities:

Evaluate the technological capabilities of the FPC manufacturer. Check if they utilize advanced manufacturing processes, cutting-edge equipment, and have the technical expertise to meet your specific requirements. A manufacturer with a commitment to staying abreast of the latest technological advancements is better positioned to deliver FPCs with superior performance and reliability.

3. Customization and Flexibility:

Different electronic applications demand varied FPC specifications. A good FPC manufacturer should offer customization options to tailor their products to your specific needs. Assess their flexibility in terms of design, materials, and production volumes. The ability to provide customized solutions ensures that the FPCs align seamlessly with your project requirements.

5. Production Capacity and Scalability:

Consider the production capacity of the FPC manufacturer and assess whether it aligns with your project timelines and volume requirements. Additionally, evaluate their scalability – the ability to handle projects of varying sizes without compromising quality. A manufacturer with sufficient production capacity and scalability is better equipped to meet your evolving needs.

6. Timely Delivery and Supply Chain Management:

On-time delivery is crucial for project success. Evaluate the FPC manufacturer's track record in meeting deadlines. Inquire about their supply chain management processes to ensure a steady and reliable flow of materials. Timely delivery is a reflection of the manufacturer's commitment to customer satisfaction and project success.

7. Customer Support and Communication:

Effective communication and reliable customer support are essential throughout the manufacturing process. Assess the responsiveness and accessibility of the manufacturer's customer support team. Clear and transparent communication channels contribute to a smoother collaboration and help address any concerns or modifications promptly.

9. Environmental and Ethical Practices:

Increasingly, companies are considering the environmental and ethical practices of their manufacturing partners. Inquire about the FPC manufacturer's commitment to sustainability, recycling, and adherence to ethical labor practices. Choosing a manufacturer with environmentally conscious practices aligns with modern corporate responsibility standards.

Ucreate is a leading flexible circuit board supplier with more than 19 years. All our flex boards meet ISO9001, ISO14001,UL,CE,RoHS & Reach. Whether only one prototype FPC or mass productions, we can offer you for all you need.

Just send you Gerber Files to sales@ucreatepcb.com, our PCB engineers will make your idear to real product.

Related Posts:

1.Why use flexible circuit boards?

2.The Significance of Flexible PCB Prototyping

3.Top 10 PCB Circuit Board Manufacturers in China

4. What is the difference between FPC flexible boards and PCB rigid boards?

Welcome to consult our sales engineer with BOM list and Gerber file