Categories

Recent Posts

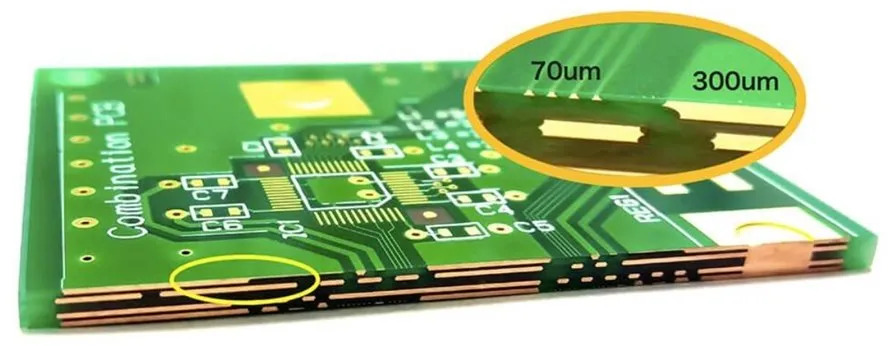

Thick copper sheet is a commonly used electronic base material in modern electronic circuits and power transmission, among other areas. Typically, the copper foil thickness of standard circuit boards ranges from 1oz (~35μm) to 2oz (~70μm), whereas the copper foil thickness of thick copper boards is usually more than 2oz, typically up to 3oz (~105μm) or higher. It has a thicker layer of copper compared to regular thin copper boards, which makes it unique in many ways.

I. Advantages

1. Strong current-carrying capacity

High current carrying: thick copper layer, like a thicker water pipe can pass more electricity, suitable for high-power equipment to transmit current, not easy to overheat. Like high-power electronic equipment, such as industrial power supply, electric vehicle charging pile, need to transmit a lot of current, thick copper can easily handle, and in the case of the same line width, than ordinary thin copper can pass a much larger current, so it is not easy to overheat, so that the circuit is more stable and reliable.

Reduce resistance loss: According to physical knowledge, the resistance is related to the cross-sectional area of the conductor, the larger the cross-sectional area, the smaller the resistance. The larger the cross-sectional area, the lower the resistance. A thick copper plate with a large cross-sectional area has a small resistance, which results in less power loss during current transmission and high efficiency of power transmission.

2. Good heat dissipation performance

Wide range of heat dissipation channels: copper when the thick copper plate in the circuit work produced heat, the heat can be relatively fast through the copper plate conduction out. For example, in the CPU power supply circuit of the computer motherboard, thick copper plate can quickly CPU generated a large amount of heat emitted to prevent localized overheating, like a layer of strong protection to the cooling system, which can extend the service life of electronic equipment.

Good synergy with heatsinks: Easy to connect with heatsinks, its thicker characteristics make it easy to use screws, thermal conductive adhesive, etc. and heatsinks tightly combined, so that the heat can be more quickly conducted to the heatsinks, further improving the heat dissipation effect. In the power supply modules of high-end servers, this combination ensures that the temperature of the power supply system is always kept within the appropriate range when running at high loads.

3. High mechanical strength

Strong Deformation Resistance: Thick copper boards are thicker and more structurally sound than thin copper boards. In the circuit board production process, such as welding temperature changes, equipment assembly may produce collision and extrusion of these thermal stresses and mechanical external forces, thick copper plate is not easy to bend, deformation, and is conducive to the connection of the various parts of the multilayer circuit board.

Easy to install and fix: in the installation of thick copper pcb to the equipment chassis or other structural components, it can be well fixed. For example, in the industrial automation equipment in the control circuit board, thick copper plate can be mounted on the chassis mounting bracket is stable, not because of equipment vibration and loosening, so as to ensure stable operation of the equipment.

II. Disadvantages

1. Difficulty in processing

Difficulty in drilling: when drilling because of the thick copper layer, the cutting force will become larger, the drill bit is badly worn and easy to break, which will lead to slower processing speed, increase cost and time.

Etching precision is low: in the etching of thick copper plate, to remove the unwanted copper layer, but because of the copper thickness, the etching solution needs to be used for a longer time. In this process, it is easy to etch unevenly, like the phenomenon of side etching is more likely to occur, which will affect the accuracy and quality of the line. For some of the line precision requirements of higher-end products, such as high-end cell phone motherboards, this problem is more serious.

2. High cost

High material cost: Thick copper boards have to use more copper, so when buying raw materials, the cost is higher. And the price of copper has been fluctuating, which makes the material cost of thick copper plate is also not very stable. For those low-cost electronic products that are mass-produced but not highly profitable, the high material cost of thick copper plates can pose a challenge in controlling product costs.

High processing cost: Due to the high processing difficulty of thick copper plate, it will make the processing time longer, the equipment wear and tear more serious, and the labor cost will also increase. So for some small quantities, many varieties of electronic products, the use of thick copper plate, each product's fixed costs (such as equipment commissioning, mold production costs) will be very high, it is difficult to have an advantage in the market price.

3. Poor flexibility

Modification difficulties: thick copper board production is completed to modify or adjust the line trouble, because the cost of modifying the thick copper board is very high, and may break the entire circuit board. This makes it less friendly to adjustments and iterations in the product development process, which is worse once modifications are needed.

Thick copper plate with its current-carrying capacity, good thermal performance and mechanical strength and other advantages in many areas have an important role, but it also exists in the processing difficulty, high cost and poor flexibility and other shortcomings. When doing electronic circuit design, engineers have to be based on specific product requirements, costs and other factors, to consider whether to use thick copper plate.

If you have any demands or questions about Thick Copper Plate, please feel free to contact us, we will provide you with one-stop service.

Email : Sales@ucreatepcb.com

Welcome to consult our sales engineer with BOM list and Gerber file